At 3Dfils we know how important a quality filament is when it comes to achieving a perfect 3D print. That is why on this page we are going to explain everything we do to offer you a premium quality filament.

In 3Dfils we have developed checkFIL, a quality control software in real time that allows us to know the quality of the filament in real time while it is being produced and that controls all the parameters of the manufacturing process to avoid deviations from the established tolerance .

In this way, each coil we produce is unique and its traceability can be fully tracked from when the raw material arrives until it is sent to the customer.

The most important parameters that we monitor are the following:

Diameter

We use two-axis laser sensors to constantly measure the diameter of the filament. Traditionally, single or dual axis sensors have been used, but offering only the average of both measurements. In this way it is not possible to know the actual quality of the filament.

In 3DFils when we give you a tolerance value it refers to a real measurement of one of the two axes of the filament and not to an average of these.

Ovality

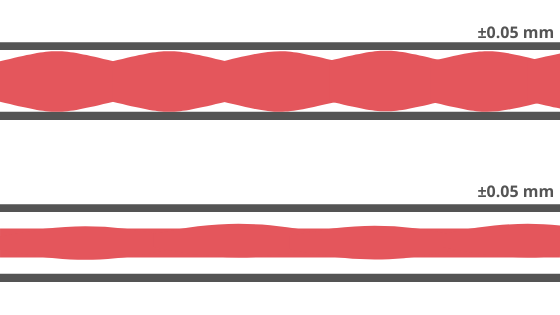

Ovality is a parameter that has not been taken into account in the 3D printing filament industry. Most companies that measure diameter on two axes tend to use the average of both to calculate their manufacturing tolerance. This means that filaments with equal mean diameters can have a very different performance when printing.

.png)

This is where ovality comes in. Ovality is a parameter that relates the measurements of both axes to indicate the difference between them. A very large ovality can cause printing problems and / or jams because although the mean diameter is correct, one of the axes is greater than tolerance.

Standard deviation

Giving just the maximum tolerance is not enough. Two filaments that share the same maximum tolerance can print in very different ways.

That is why in 3DFils we wanted to add one more parameter to quality control, the standard deviation. This parameter measures the variation in diameter throughout the entire filament. A low standard deviation means that all measurements taken are very close to the mean diameter.

What quality do we offer?

At 3DFILS we assure you that all our coils will meet at least these quality parameters:

| Maximum tolerance: | < 0.05mm |

| Ovality: | < 2% |

| Standard deviation: | < 0.02mm |

These numbers are indicative and depending on the material and diameter they may be smaller. To know the specific quality of a filament, it is best to go to its product page.

Check it out for yourself:

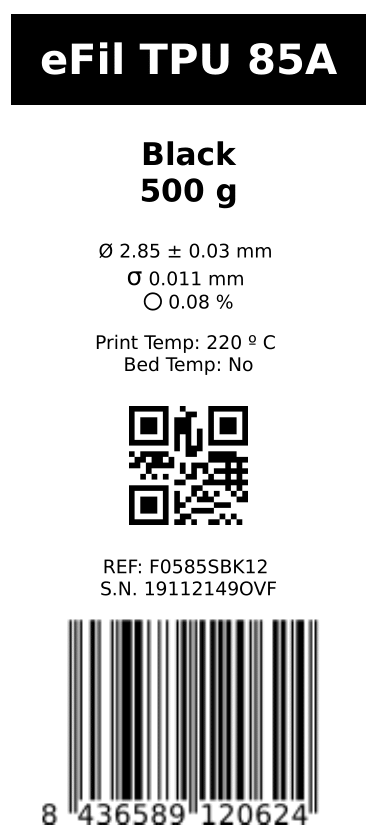

So that you can check the quality of your filament we have implemented all the quality data on the stickers of each coil. In this way you can find in the box the unique data of the coil that you are going to use accompanied by its unique identifier with which we can know meter by meter all the characteristics of the coil.

On the sticker you will first find the diameter of the filament accompanied by the maximum tolerance of that coil.

Below you have the standard deviation of that specific coil.

Finally you can see the ovality expressed as a percentage.

For any query regarding your coil you will have to use the Spool Number (S.N) that appears at the bottom of the sticker.