At 3DFils, we know that filament quality is critical for achieving precise and consistent 3D prints. Every filament specification—whether its diameter, tolerance, or ovality—exists for a reason: to ensure the material performs exactly as expected in the printer.

To achieve this, we developed checkFIL , a real-time control system that monitors every stage of the manufacturing process. This way, each reel is tracked from raw material to final product, ensuring it remains within established tolerances.

Key quality parameters:

Diameter

Diameter is the measurement from one end of the filament to the other in a cross-section. Filaments typically come in standard sizes, such as 1.75 mm or 2.85 mm.

Tolerance

A tolerance, for example ±0.05mm, indicates how much that diameter can vary on each spool. In other words, a 1.75mm filament measuring ±0.05mm can vary between 1.70mm and 1.80mm. Although the difference may seem minimal, in 3D printing terms this translates into significant variations that can affect extrusion accuracy.

Ovality

Ovality assesses whether the filament maintains a perfectly circular shape throughout its entire length. A filament that deforms and becomes oval can cause difficulties for the printer's feed system to properly grasp it, leading to problems such as overextrusion or even jamming.

.png)

Standard Deviation

We measure the variation in diameter along the filament. A low standard deviation means that most sections of the filament are close to the ideal value, resulting in a more uniform and predictable material.

What quality do we offer?

Our coils meet at least these parameters:

| Maximum tolerance: | < 0.05mm |

| Ovality: | <2% |

| Standard deviation: | <0.02mm |

These values are for reference only and may vary depending on the material and specific diameter. For exact quality, please refer to the respective product page.

Check the Quality for Yourself

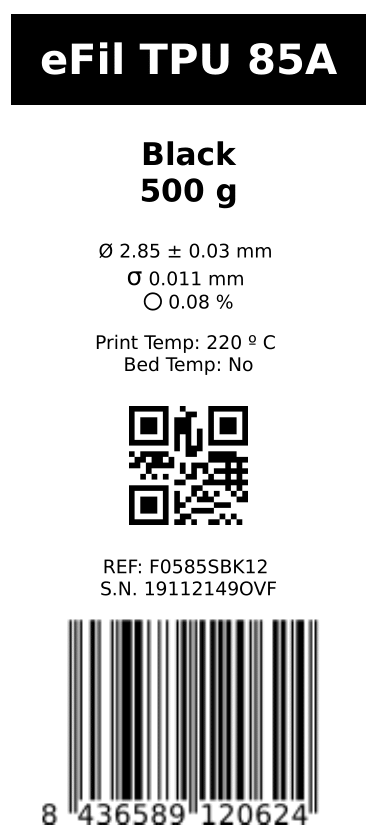

Each reel includes a label with all the quality data and a unique identifier, allowing each stage to be tracked from manufacturing to delivery.